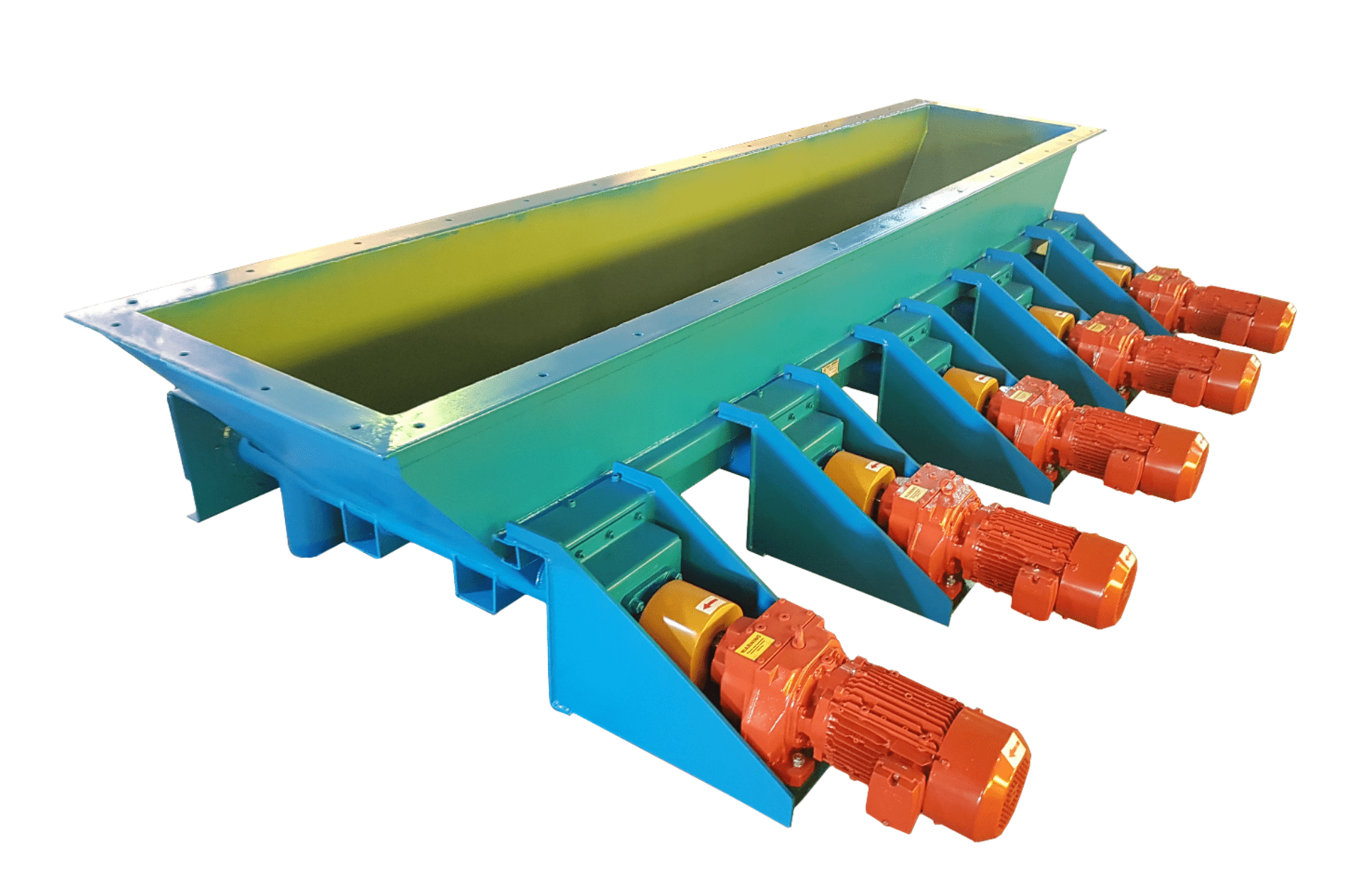

Equipment is manufactured in a way that prevents abrasion of the material to ensure the equipment performs and exceeds the lifespan of minimum12 months during normal operations.

Many bulk materials are easily, effectively and efficiently handled by screw conveyors and the essential characteristics of the material handled must be defined.

Primarily, size, flow ability and degree of abrasiveness are but three important considerations and are the limit of the design criteria of the “Self-Select System” operated unless the selectors prior experience and knowledge understands and is aware of other overriding characteristics, e.g., contamination, degradation, pressure effects, fluffiness etc.

Initially covers screw conveyors of 150, 200, 250, 300 diameters with standard applications manufactured both blades and troughs in 3mm plate whereas on heavier applications 5mm is available. A choice of both inboard and outboard bearing end plates is also made and although the outboard type is generally used on abrasive materials it can also be selected for the standard duties on fine powders etc.